Materials Science

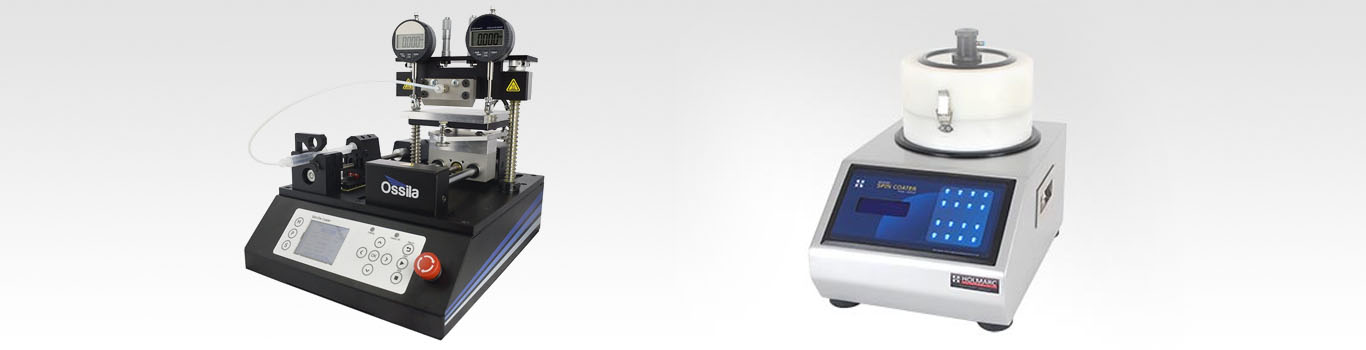

Slot-Die Coater

The Ossila slot-die coating system offers the following benefits for your research:

- Stainless-steel slot-die head to give you an even solution distribution

- Easy to use in-built software - the system has its own independent digital control system, so you don't need to connect it to an external computer

- Interchangeable shims - higher versatility for varying channel thickness

- In-built Ossila syringe pump - so you can have synchronised starting times and don't need a separate external syringe pump

- Heated stage allowing temperature to be controlled up to 120°C - giving you improved solution wetting

- A travel distance of up to 10cm - Allowing you to scale-up device sizes (up to a maximum of 50cm2)

- Motorised stage with speeds varying from 1mm/m to 10mm/s - offering a wide processing window for control of the meniscus

- Digital height gauges accurate to 1um, allowing for precise stage levelling

- Precision alignment with our simple-to-use 3-point levelling system

- Micrometers for precise positioning of the head relative to the substrate

Spin Coater

Why Go Vacuum-Free?

The majority of spin coaters in the market use vacuum pumps to hold the substrates while they spin. Unlike the rest, the Ossila Spin Coater features an innovative chuck that does not require a vacuum. Instead, substrates are held in place by recesses cut into a polypropylene chuck, allowing excess coating material to be drained away.

Thin substrates are likely to be warped inwards by vacuum chucks, affecting coating uniformity. This reduces the quality and performance of devices. Ossila's vacuum-free chucks ensure an even film distribution by keeping your substrates flat and free from damage - even if they are flexible substrates.

Vacuum-fed spin coaters can only be set up where a vacuum line is available, and are likely to remain where they are set up, taking up space even when not in use. By not needing a vacuum line, the Ossila Spin Coater can be set up anywhere with a single mains socket. The same Ossila Spin Coater can be used on the benchtop, in a fume hood, and a glove box - all in the same day if needed, thanks to its easy setup and compact size.

Most spin coaters are burdened by the hidden cost of vacuum pumps that are usually excluded from the full system price. Vacuum pumps are prone to breaking, resulting in expensive repairs and delays. This is mainly caused by excess solvents being sucked into the vacuum line, damaging the internal components.

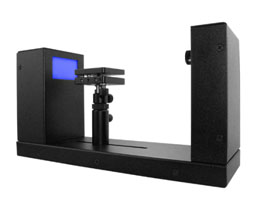

Contact Angle Goniometer

Features

Affordable - Emerging camera technologies have allowed high-resolution images to be captured for much lower material costs. This means we can reduce the price of contact angle measurements, without compromising on quality.

Simple to Use - The system comes complete with PC software that provides a simple and intuitive interface for contact angle measurements. We also provide user guides and videos to help you get the most out of your experiments (coming soon).

Compact Size - The small footprint of the system lets you perform measurements in labs even when space is lacking. With a total bench area of 10 cm x 30 cm, you won't need to devote a whole desk to a single piece of equipment.

Easier Ink Optimisation - A low price and small size makes it possible for labs to have multiple systems. This enables constant access to contact angle measurements, without needing to wait in line for a colleague to finish using it. The continuous feedback you gain from in-line contact angle measurements will speed up your ink formulation process.

High-Resolution Video - Take quality videos of your droplets using the high-resolution camera and a specially selected imaging lens. Watch and edit your videos however you like by exporting them as .avi files.

Rapid Image Capture - The high frame rate of the system allows you to study the wetting process in detail, and gain increased insight into film formation.